FOXBORO AD908AC module

Technical data of product parameters

When set for STI mode, the PID AD908AC executes and updates the CV every time the

PID instruction is scanned in the control program. When you select STI,

program the PID instruction in the STI interrupt subroutine. The STI routine

should have a time interval equal to the setting of the PID “loop update”

parameter. Set the STI period in word S:30. For example, if the loop update

time contains the value 10 (for 100 ms), then the STI time interval must also

equal 100 (for 100 ms).The loop update (word 13) is the time interval between PID calculations. The AD908AC

entry is in 0.01 second intervals. Enter a loop update time five to ten times

faster than the natural period of the load. The natural period of the load is

determined by setting the reset and rate parameters to zero and then increasing AD908AC

the gain until the output begins to oscillate. When in STI mode, this value

must equal the STI time interval value loaded in S:30. The valid range is 0.01 to

10.24 seconds. See page 11-12 for help entering STI setpoint.Scale your analog input by calculating the slope (or rate) of the analog

input range to the PV range (0 to 16383.) For example, an analog input

with a range of 4 to 20mA has a decimal range of 3277 to 16384. The

decimal range must be scaled across the range of 0 to 16383 for use as

PV. AD908AC

2. Scale the CV to span evenly across your analog output range. For

example, an analog output which is scaled at 4 to 20mA has a decimal

range of 6242 to 31208. In this case, 0 to 16383 must be scaled across

the range of 6242 to 31208.

Once you have scaled your analog I/O ranges to/from the PID

instruction, you can enter the minimum and maximum engineering units

that apply to your application. For example, if the 4 to 20mA analog

input range represents 0 to 300 PSI, you can enter 0 and 300 as the

minimum (Smin) and maximum (Smax) parameters respectively. The

Process Variable, Error, Setpoint, and Deadband are displayed in

engineering units in the PID Data Monitor screen. Setpoint and

Deadband can be entered into the PID instruction using engineering

units.

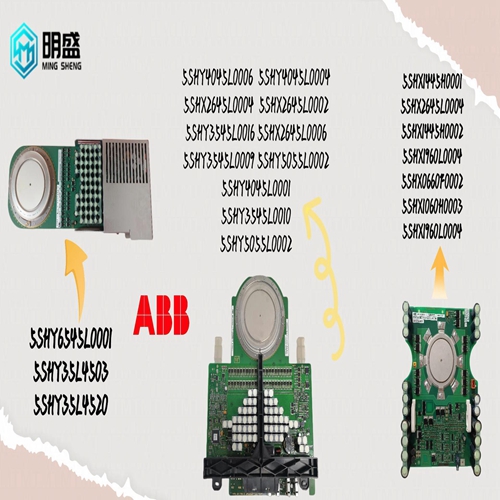

Product picture display

bout us service idea

The company takes production suspension control system parts and components as its dominant products

As long as it is what you want, I can help you find it! Good price! Our purpose:

Build customer relationship with sincerity

Obtain customer satisfaction through service

Win the trust of customers with products

Improve work efficiency with actions

Please contact us for the products you need urgently!

You can’t find the product. Please contact us!

Products you can’t buy. Please contact us!

Email: onewwww@foxmail.com

Introduction to main products

Focus on DCS, PLC, robot control system and large servo system.

Main products: various modules/cards, controllers, touch screens, servo drives.

Advantages: supply imported original products, professional discontinued parts, fast delivery, accurate delivery time,

Main brands include ABB Bailey, GE/FANC, FOXBORO, Invensys TRICONEX, Bentley BENTLY, A-B Rockwell, Emerson EMERSON, OVATION, MOTOROLA, XYVOM, Honeywell HONEYWELL, Rexroth, KUKA, NI, DEIF, Yokogawa, Woodward WOODWARD, Ryan, Schneider SCHNEIDER, Yaskawa, Moog MOOG, PROSOFT and other brands

reminder

For more products, please contact the email for inquiry onewwww@foxmail.com

This article from the temporal Ming sheng automation equipment co., LTD.,

link: http:www.onewwww.com

Reviews

There are no reviews yet.