ABB DAPU100 3ASC25H204 control board

Technical data of product parameters

The following example shows how DAPU100 3ASC25H204 to use the Discrete Input Interrupt to

control a high-speed application. In the example, the DII is used to ensure that

all bottles exiting a filling and capping machine have their caps installed.

The bottle proximity switch is used as the DII input. When a bottle passes the

proximity switch, the processor executes the DII subroutine. In the subroutine

the processor reads the state of the cap proximity switch. If the cap is installed, DAPU100 3ASC25H204

the chute solenoid does not energize; allowing the bottle to continue down the

line. If the cap is missing, the chute solenoid energizes, causing the defective

bottle to divert down the chute and into the reject bin.This function allows a specialty I/O module to interrupt the normal processor

operating cycle in order to scan a specified subroutine file. Interrupt operation

for a specific module is described in the user’s manual for the module.

Not all specialty I/O modules are capable of generating I/O interrupts. Refer

to the user manual of the specific specialty I/O module to see if it supports

this feature. For example, you cannot use a standard discrete I/O module to

accomplish an I/O event-driven interrupt.• When you are configuring the specialty I/O module slot with the DAPU100 3ASC25H204

programming device, make sure you program the “ISR” (interrupt

subroutine) program file number (range 3 to 255) that you want the

processor to execute when the module generates an interrupt. Specialty

I/O modules that create interrupts should be configured in the lowest

numbered I/O slots. DAPU100 3ASC25H204

• Create the subroutine file that you have specified as the ISR number in

the I/O module slot configuration.The Interrupt Subroutine (INT) instruction should be the first instruction in

your ISR. This identifies the subroutine file as an I/O interrupt subroutine.

The ISR contains the rungs of your application logic. You can program any

instruction inside an ISR except a TND, REF, or SVC instruction. IIM or

IOM instructions are needed in an ISR if your application requires immediate

update of input or output points. Terminate the ISR with an RET (return)

instruction.

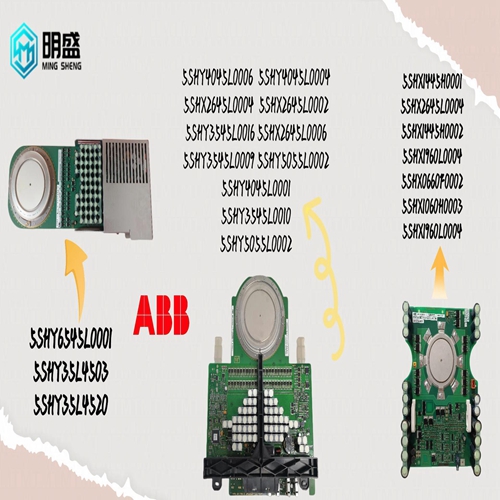

Product picture display

bout us service idea

The company takes production suspension control system parts and components as its dominant products

As long as it is what you want, I can help you find it! Good price! Our purpose:

Build customer relationship with sincerity

Obtain customer satisfaction through service

Win the trust of customers with products

Improve work efficiency with actions

Please contact us for the products you need urgently!

You can’t find the product. Please contact us!

Products you can’t buy. Please contact us!

Email: onewwww@foxmail.com

Introduction to main products

Focus on DCS, PLC, robot control system and large servo system.

Main products: various modules/cards, controllers, touch screens, servo drives.

Advantages: supply imported original products, professional discontinued parts, fast delivery, accurate delivery time,

Main brands include ABB Bailey, GE/FANC, FOXBORO, Invensys TRICONEX, Bentley BENTLY, A-B Rockwell, Emerson EMERSON, OVATION, MOTOROLA, XYVOM, Honeywell HONEYWELL, Rexroth, KUKA, NI, DEIF, Yokogawa, Woodward WOODWARD, Ryan, Schneider SCHNEIDER, Yaskawa, Moog MOOG, PROSOFT and other brands

reminder

For more products, please contact the email for inquiry onewwww@foxmail.com

This article from the temporal Ming sheng automation equipment co., LTD.,

link: http:www.onewwww.com

Reviews

There are no reviews yet.