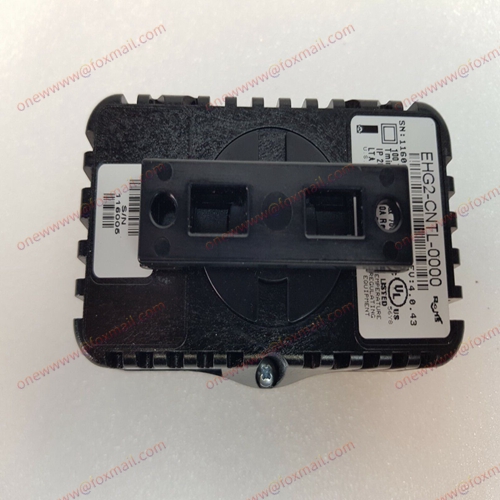

The AMAT 0020-22920 Digital Quantity Control Board is a key component used in semiconductor manufacturing equipment. It is designed and manufactured by Applied Materials, Inc. (AMAT), a leading supplier of semiconductor manufacturing equipment, services, and software.

The Digital Quantity Control Board plays an important role in controlling the amount of material that is deposited onto a wafer during the manufacturing process. It is responsible for measuring and regulating the flow of gas or liquid precursors, which are used to deposit thin films onto the wafer.

Some key features of the AMAT 0020-22920 Digital Quantity Control Board include:

- High-precision measurement capabilities: The board uses advanced sensors and algorithms to measure the flow rate of the precursor gas or liquid with high precision. This enables it to accurately control the amount of material that is deposited onto the wafer.

- Flexible configuration options: The board can be configured to support different types of gases or liquids, and it can be customized to meet the specific requirements of different manufacturing processes.

- Real-time monitoring and control: The board provides real-time monitoring and control of the precursor flow rate, allowing operators to adjust the settings and optimize the process for maximum efficiency and quality.

- Robust and reliable design: The board is designed to withstand the harsh environment of semiconductor manufacturing, including high temperatures, corrosive chemicals, and other challenging conditions. It has a robust and reliable design that ensures consistent performance and minimizes downtime.

In summary, the AMAT 0020-22920 Digital Quantity Control Board is a critical component in semiconductor manufacturing equipment that plays a crucial role in controlling the amount of material that is deposited onto a wafer. Its high-precision measurement capabilities, flexible configuration options, real-time monitoring and control, and robust design make it an essential tool for semiconductor manufacturers.