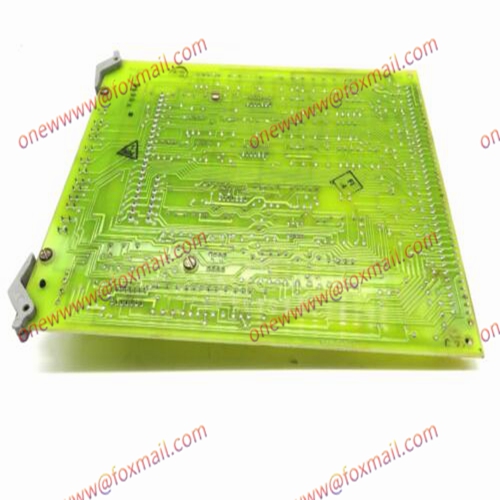

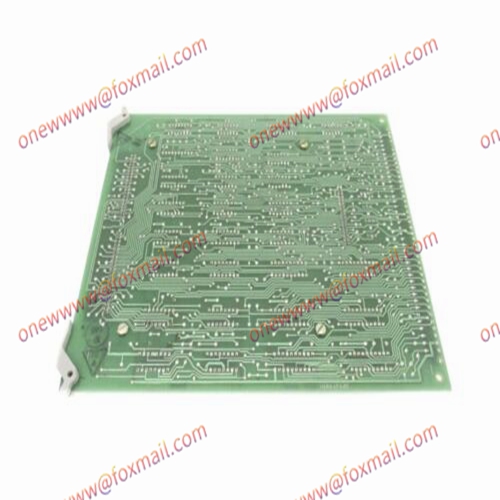

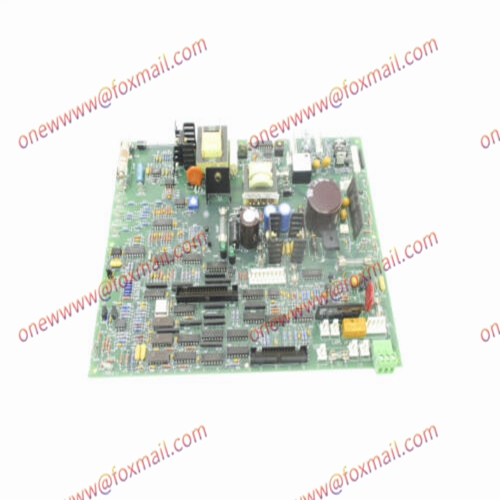

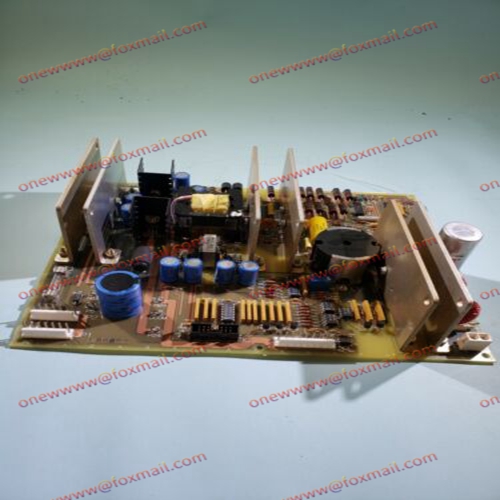

GE DS200SDCIG2A Industrial Control Card Details Introduction

The GE DS200SDCIG2A is a specific model of an industrial control card manufactured by GE (General Electric). While I don’t have access to the specific details of this particular card, I can provide you with a general overview of industrial control cards and their typical functions.

Industrial control cards, also known as control interface cards or control input/output (I/O) cards, are components used in industrial control systems to interface with various devices and equipment. These cards provide the necessary input and output interfaces to communicate with field devices and exchange signals with the control system.

Here are some key features and functions that industrial control cards typically offer:

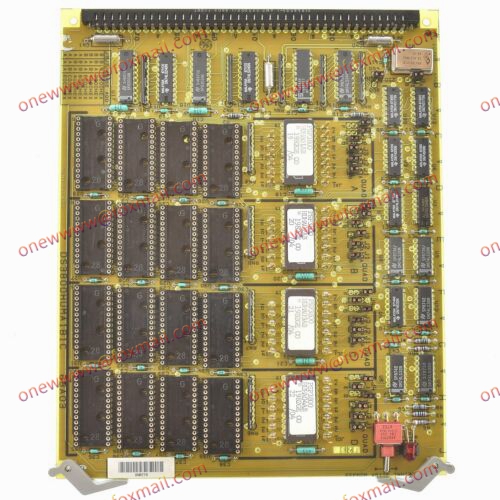

- Input/Output Channels: Control cards include a specific number of input and output channels to receive signals from field devices and send control signals to actuators or other equipment. These channels can handle different types of signals, such as analog or digital signals.

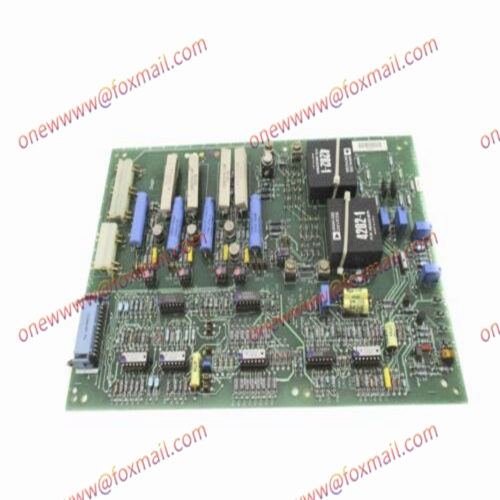

- Signal Conditioning: Industrial control cards often include signal conditioning capabilities to ensure accurate and reliable measurement of input signals. Signal conditioning may involve amplification, filtering, isolation, or other techniques to enhance the quality of the signals.

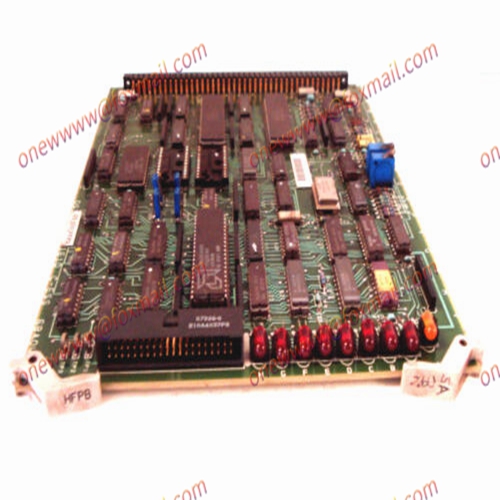

- Communication Protocols: Control cards support various communication protocols to interface with the control system and other devices in the network. Common protocols include Modbus, Profibus, EtherNet/IP, and others, enabling seamless integration into the control infrastructure.

- Synchronization and Timing: Control cards may have synchronization capabilities to ensure precise timing and coordination with other components in the control system. This is particularly important in applications where timing accuracy is critical.

- Diagnostic and Monitoring Features: Industrial control cards often provide diagnostic tools and monitoring capabilities to detect faults, track performance, and provide insights into the health and status of the connected devices and processes.

- Compatibility and Integration: Control cards are designed to be compatible with specific control systems or platforms, ensuring smooth integration and interoperability with the overall control system.

To obtain detailed information about the GE DS200SDCIG2A Industrial Control Card, I recommend contacting GE directly or referring to their official documentation and product support resources. They will be able to provide you with the specific details, technical specifications, and application guidelines for this particular control card.