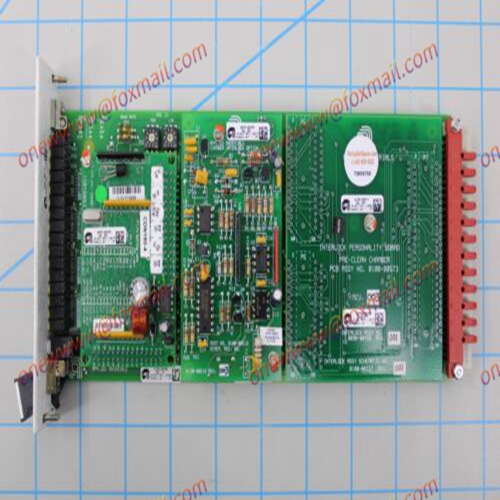

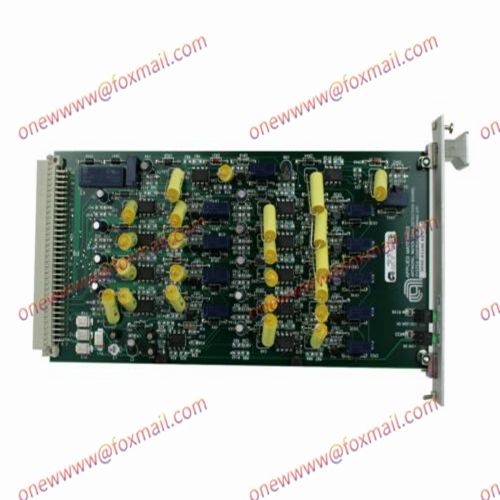

AMAT 0190-40016 I/O Module Details Introduction

The AMAT 0190-40016 I/O (Input/Output) Module is a critical component in semiconductor manufacturing equipment, designed and manufactured by Applied Materials, Inc. (AMAT), a leading supplier of semiconductor manufacturing equipment, services, and software.

The I/O module is responsible for connecting various components and sensors in the equipment and transferring data between them. It is a key interface between the control system and the equipment, enabling operators to monitor and control the manufacturing process.

Some key features of the AMAT 0190-40016 I/O Module include:

- High-speed data transfer: The module is designed to transfer data between components and sensors at high speed, enabling real-time monitoring and control of the manufacturing process.

- Compatibility with various sensors and components: The module is compatible with a wide range of sensors and components used in semiconductor manufacturing, enabling it to be used in various equipment and processes.

- Scalable architecture: The module is designed to be easily scalable, allowing it to accommodate changes in the manufacturing process and equipment configuration.

- Robust and reliable design: The module is designed to withstand the harsh environment of semiconductor manufacturing, which involves high temperatures, corrosive chemicals, and other challenging conditions. It has a robust and reliable design that ensures consistent performance and minimizes downtime.

- Easy installation and maintenance: The module has a compact and lightweight design, making it easy to install and maintain in the equipment.

In summary, the AMAT 0190-40016 I/O Module is a critical component in semiconductor manufacturing equipment that enables the transfer of data between different components and sensors, enabling real-time monitoring and control of the manufacturing process. Its high-speed data transfer, compatibility with various sensors and components, scalable architecture, robust and reliable design, and easy installation and maintenance make it an essential tool for semiconductor manufacturers.