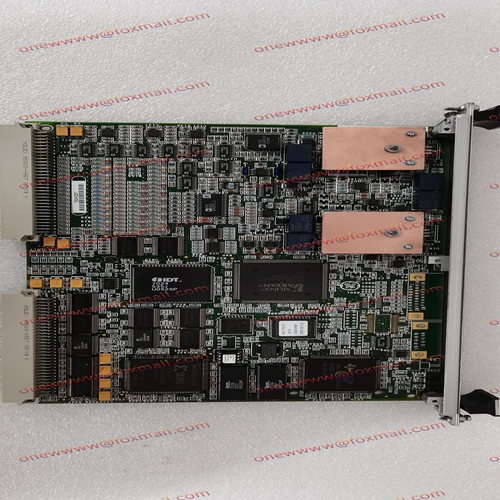

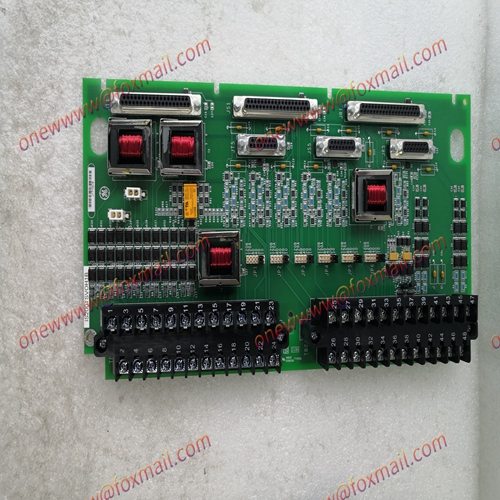

GE DS215UCLAG1B Firmware Circuit Board

The GE DS215UCLAG1B is a firmware circuit board used in the control system of gas turbines. It is responsible for running and managing the firmware that controls the operation of various components in the gas turbine system.

The firmware circuit board is a critical component that helps to ensure the reliable and efficient operation of the gas turbine. It is responsible for running the software that controls the operation of key components such as the gas turbine controller, power supply units, and communication interfaces.

The DS215UCLAG1B firmware circuit board is designed to be highly reliable and to operate in harsh industrial environments. It is built with robust materials that can withstand extreme temperatures, shock, and vibration, ensuring long-term reliability. The board also includes various protective functions such as overvoltage and overcurrent protection, which help to prevent damage to the equipment.

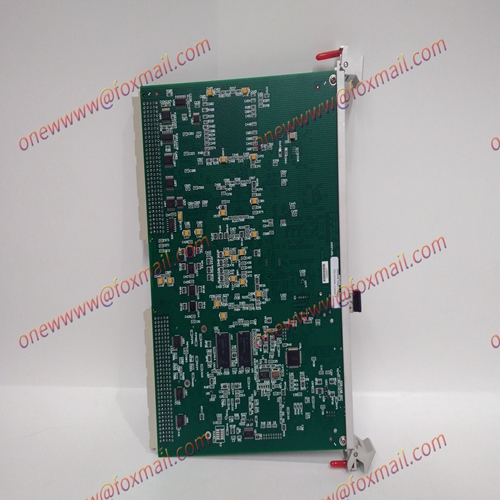

The firmware circuit board is designed to be flexible and easy to integrate with other components of a gas turbine control system. It can be programmed to suit the specific requirements of the gas turbine, and it can be connected to various communication networks for remote monitoring and control.

The DS215UCLAG1B firmware circuit board is also designed for ease of maintenance and repair. It is a modular component that can be easily replaced in the event of a failure, reducing downtime and maintenance costs.

Overall, the GE DS215UCLAG1B firmware circuit board is a critical component that helps to ensure the safe, reliable, and efficient operation of gas turbine power generation systems. It is a flexible and robust component that can be easily integrated into existing control systems, and it is built to withstand the extreme conditions of industrial environments.