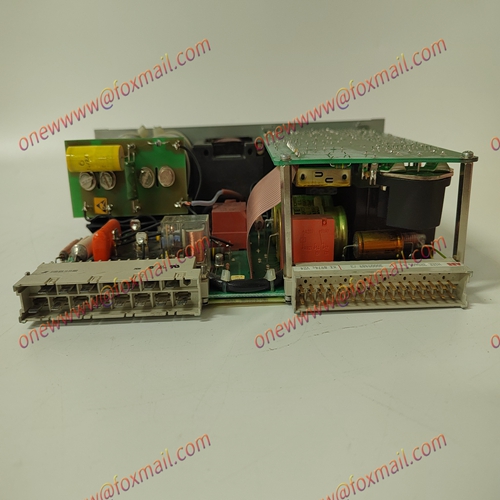

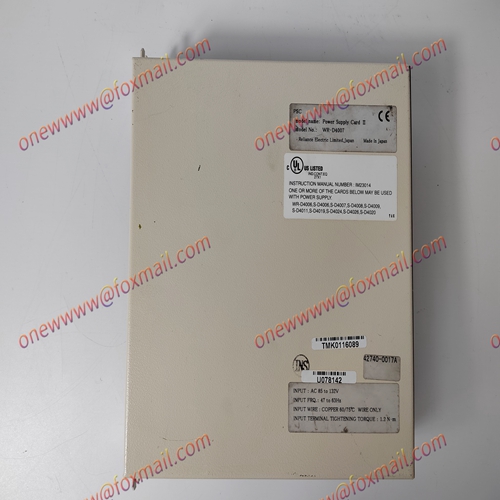

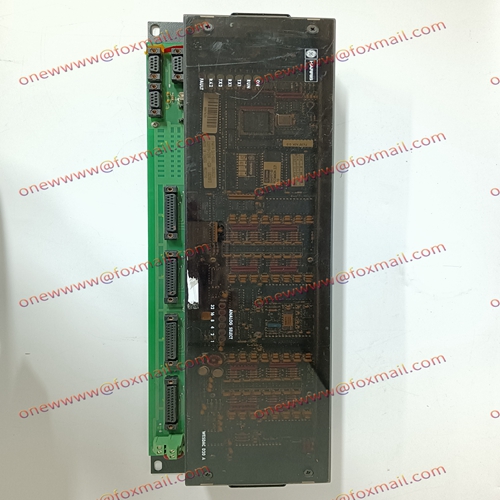

ABB KX8974c V24 HIEE320606R1 system module details

The ABB KX8974C V24 HIEE320606R1 is a system module used in ABB’s Symphony Harmony/INFI 90 distributed control systems. This module is designed to perform a variety of functions related to system control and communication.

Some of the key features and functions of the KX8974C module include:

- Communication support: The module supports a variety of communication protocols, including Ethernet, TCP/IP, and UDP.

- I/O processing: The module provides I/O processing capabilities, allowing it to interface with field devices and process signals.

- Redundancy support: The module supports redundancy, allowing for reliable system operation in mission-critical applications.

- Event processing: The module provides event processing capabilities, allowing it to handle alarms and other system events.

- Data storage: The module has on-board storage capabilities, allowing it to store data and system configuration information.

- Hot-swappable design: The module is hot-swappable, meaning it can be replaced without shutting down the system, minimizing downtime.

Overall, the ABB KX8974C V24 HIEE320606R1 system module is a versatile and reliable component of ABB’s Symphony Harmony/INFI 90 control systems. It provides a range of essential functions related to system control and communication, ensuring efficient and reliable operation of the system.