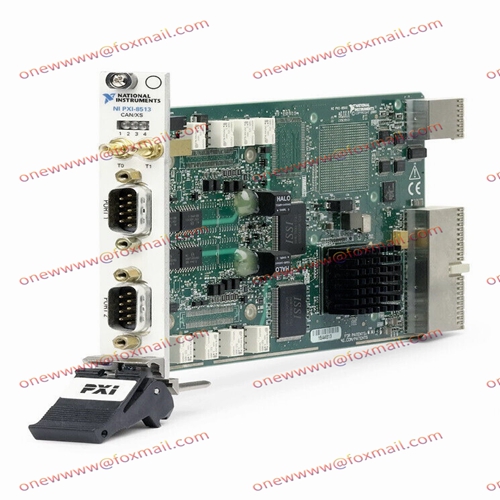

NI PXI-8513/2 interface module

NI PXI-8513/2 is an interface module that belongs to the National Instruments (NI) product line. The following is a detailed introduction to the NI PXI-8513/2 interface module:

The NI PXI-8513/2 interface module is a high-performance multi-channel CAN (Controller Area Network) interface module designed to achieve CAN bus communication on the PXI (PCI eXtensions for Instrumentation) platform.

The following are some main features and functions of the NI PXI-8513/2 interface module:

CAN interface: This module provides multiple CAN interface channels for communication with CAN bus devices. It supports standard CAN and high-speed CAN communication protocols and is suitable for a wide range of CAN applications.

High performance data transmission: NI PXI-8513/2 supports high-speed data transmission, enabling fast and reliable CAN communication. It may have high transmission rates and low latency to meet the needs of real-time data communication.

Multi channel support: This module provides multiple CAN channels, allowing communication with multiple CAN devices simultaneously. This makes it suitable for applications that require data exchange with multiple devices simultaneously.

Flexible triggering and synchronization functions: NI PXI-8513/2 may support flexible triggering and synchronization functions to meet the data collection and communication control requirements of specific applications. It supports multiple triggering modes and sources, enabling precise time synchronization.

Driver software and development tools: This module is equipped with corresponding driver software and development tools to facilitate user configuration, data collection, and communication programming of the module. NI provides a powerful software platform and development tools, supporting multiple programming languages and environments.

PXI platform compatibility: NI PXI-8513/2 complies with PXI standards and can seamlessly integrate with other PXI modules and devices to build customized control and communication systems.