AMAT 0660-00090 Digital Quantity Control Board Details Introduction

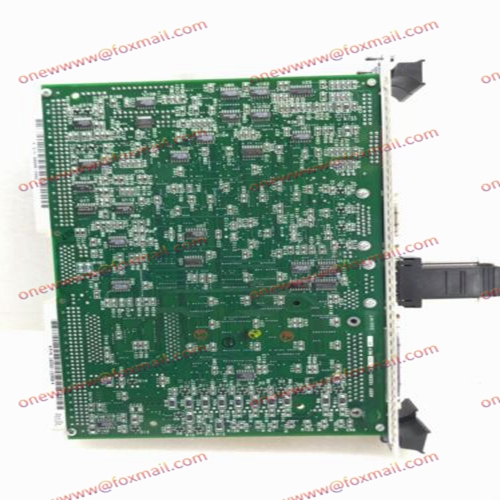

The AMAT 0660-00090 is a digital quantity control board used in industrial automation applications, particularly in the semiconductor manufacturing industry. It is designed to provide high-speed digital control of industrial processes, such as chemical mixing, wafer cleaning, and plasma processing.

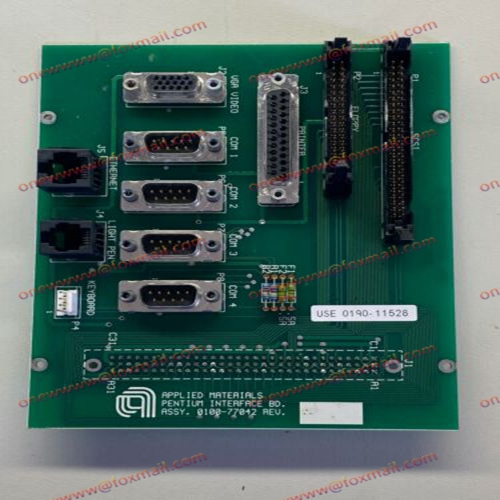

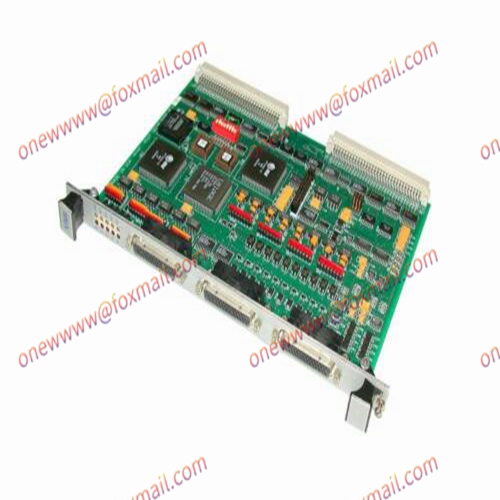

The AMAT 0660-00090 digital quantity control board features a high-performance processor that can execute complex control algorithms with speed and precision. It also includes a range of input/output (I/O) ports for interfacing with sensors, valves, pumps, and other devices. The module supports a variety of communication protocols, including Ethernet, RS-232, and RS-485, which enables it to connect to other devices in the production line.

One of the key benefits of the AMAT 0660-00090 digital quantity control board is its ability to provide precise control of process quantities, such as flow rate, pressure, and temperature. The board can be programmed to control a wide range of process control tasks, from simple on/off control to more complex proportional-integral-derivative (PID) control. It also has a user-friendly programming interface that allows engineers to quickly develop and debug control code.

In addition, the AMAT 0660-00090 digital quantity control board has built-in safety features that ensure safe operation in hazardous environments. It also has a rugged design that can withstand harsh industrial environments, such as temperature extremes, shock, and vibration.

Another key feature of the AMAT 0660-00090 digital quantity control board is its ability to integrate with other industrial control systems, such as PLCs (Programmable Logic Controllers) and DCS (Distributed Control Systems). This allows for centralized monitoring and control of multiple processes and production lines.

Overall, the AMAT 0660-00090 digital quantity control board is a reliable and high-performance control solution that can help improve productivity and efficiency in a wide range of industrial automation applications, particularly in the semiconductor industry. Its precision, safety features, and integration capabilities make it a valuable addition to any process control system.