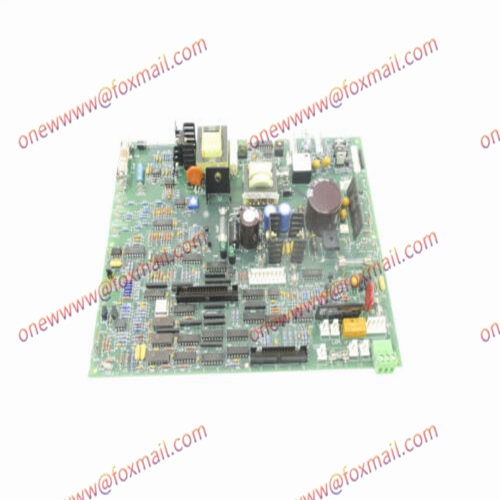

EEA-PAM-561-A-12 thyristor module details introduction

The EEA-PAM-561-A-12 is a thyristor module used for power control in industrial applications. It is designed to handle high voltage and current loads, making it suitable for a range of applications including motor control, heating, and lighting. Here are some of the details and features of this module:

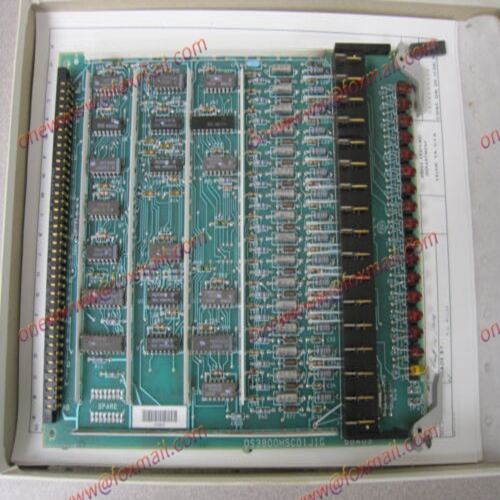

Construction: The module has a rugged construction with a metal base plate and a ceramic insulator for high electrical isolation. The module is designed to handle high thermal loads, with a maximum thermal resistance of 0.05°C/W.

Power handling: The EEA-PAM-561-A-12 thyristor module has a voltage rating of 1200 V and a current rating of 560 A. It can handle a maximum surge current of 5800 A, making it suitable for use in high-current applications.

Gate control: The module can be controlled using a low-voltage signal applied to the gate terminal. The maximum gate trigger voltage is 3 V, with a gate trigger current of 200 mA and a holding current of 150 mA.

Mounting: The module has screw terminals for power connections and fast-on terminals for control connections. It can be easily mounted on a heat sink or other suitable surface using screws.

Applications: The EEA-PAM-561-A-12 thyristor module is suitable for a range of industrial applications, including motor control, heating, and lighting. It can be used in conjunction with other power control devices such as transformers and rectifiers to provide precise and reliable power control.

Overall, the EEA-PAM-561-A-12 thyristor module is a rugged and reliable power control device that is suitable for a range of industrial applications. Its high power handling capabilities, low gate trigger voltage, and easy mounting make it a valuable component in many different types of systems.