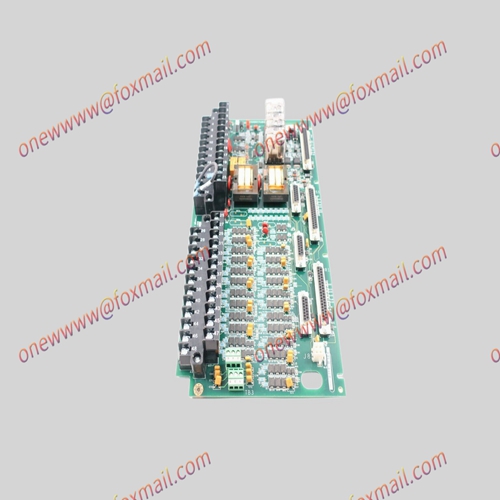

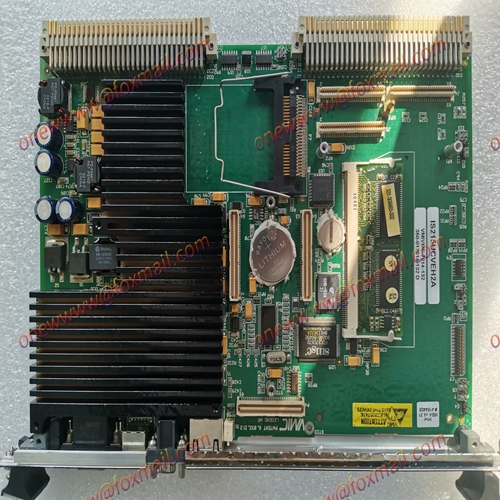

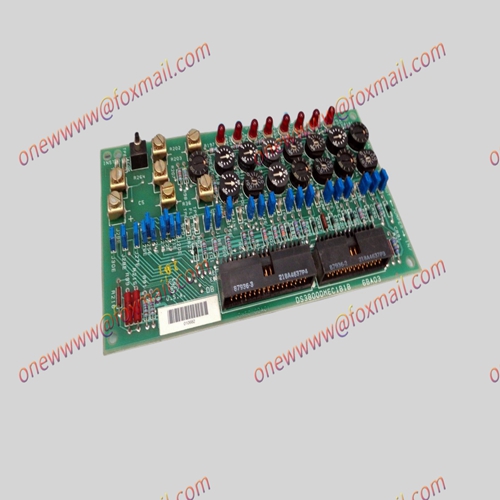

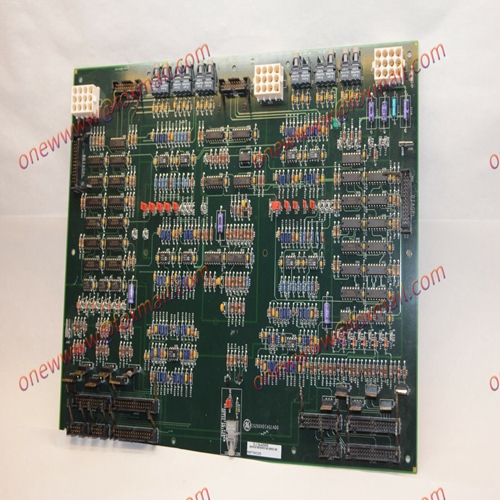

GE DS3810CLCB1A1A Input Circuit Board Details Introduction

The GE DS3810CLCB1A1A input circuit board is a component of the General Electric Speedtronic Mark VI gas turbine control system. It is responsible for providing input signal conditioning and processing for various sensors and transducers used in gas turbine operation.

The DS3810CLCB1A1A input circuit board features up to 16 channels of analog inputs, with each channel capable of accepting a range of signal types, including voltage, current, RTD, and thermocouple. The board includes a built-in microprocessor that provides advanced signal conditioning, processing, and scaling capabilities, enabling it to convert raw sensor signals into meaningful data for the control system.

The input circuit board is designed to operate within the harsh industrial environment typical of gas turbine applications. It features a ruggedized enclosure and can operate within a wide temperature range. The DS3810CLCB1A1A input circuit board also includes built-in diagnostic and troubleshooting features, including error detection and logging, to help technicians quickly identify and resolve any issues that may arise.

In summary, the GE DS3810CLCB1A1A input circuit board is a critical component of the Mark VI gas turbine control system, responsible for providing input signal conditioning and processing for various sensors and transducers used in gas turbine operation. Its advanced signal conditioning and processing capabilities, ruggedized design, and diagnostic features make it an essential part of the gas turbine control system, ensuring safe and reliable operation of the gas turbine.