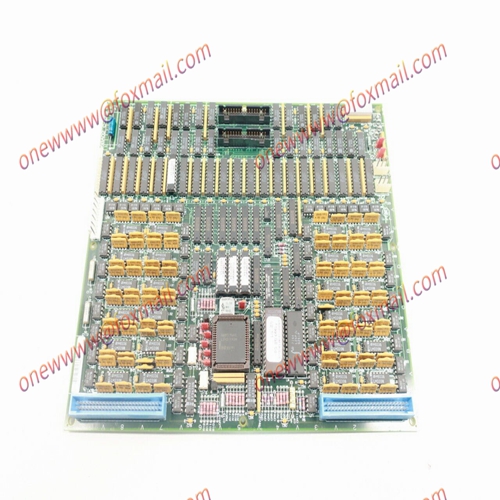

GE DS200TCQCG1BFE module power board

The GE DS200TCQCG1BFE module power board is a power supply module used in various industrial control applications. It is designed to provide power to the DS200TCQCG1BJF analog input module, which is used to receive and process analog signals from field devices.

The DS200TCQCG1BFE power board is designed to be highly reliable and efficient, providing stable power to the analog input module even in harsh industrial environments. It is also designed to be easy to install and maintain, with a modular design that allows for easy replacement and servicing.

The power board includes various protection features, such as overvoltage protection, overcurrent protection, and short-circuit protection, helping to ensure the safety and reliability of the module.

Overall, the GE DS200TCQCG1BFE module power board is an essential component of the GE DS200TCQCG1BJF analog input module system, providing stable and reliable power to the analog input module in various industrial control applications.

The GE DS200TCQCG1BFE module power board is a power supply module used in various industrial control applications. It is designed to provide power to the DS200TCQCG1BJF analog input module, which is used to receive and process analog signals from field devices.

The DS200TCQCG1BFE power board is designed to be highly reliable and efficient, providing stable power to the analog input module even in harsh industrial environments. It is also designed to be easy to install and maintain, with a modular design that allows for easy replacement and servicing.

The power board includes various protection features, such as overvoltage protection, overcurrent protection, and short-circuit protection, helping to ensure the safety and reliability of the module.

Overall, the GE DS200TCQCG1BFE module power board is an essential component of the GE DS200TCQCG1BJF analog input module system, providing stable and reliable power to the analog input module in various industrial control applications.