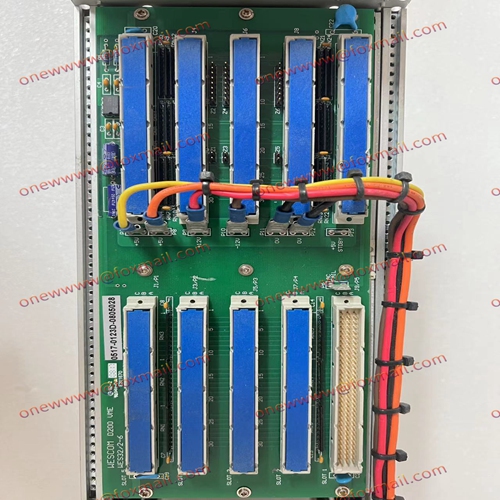

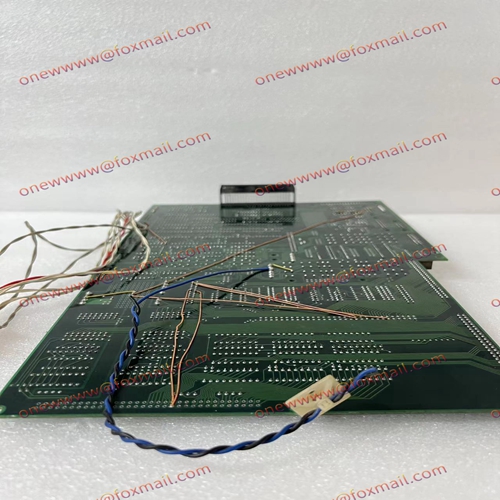

BENTLY 60M100-00 detection module

The Bently 60M100-00 detection module is a component used in machinery monitoring systems. It is designed to detect and measure vibrations and other mechanical parameters of rotating machinery such as motors, pumps, and turbines.

The 60M100-00 module is part of the Bently Nevada product line, which is a brand of machinery monitoring and protection equipment owned by Baker Hughes, a GE company. The module uses advanced sensor technology and signal processing algorithms to measure various parameters of machinery vibration, including acceleration, velocity, displacement, and frequency.

The module is typically installed on the machine casing or housing, and it includes features such as temperature compensation, self-test functions, and programmable gain settings to ensure accurate and reliable measurements. It can communicate with other components in the monitoring system using various interfaces such as analog outputs, digital outputs, and serial communication protocols.

The Bently 60M100-00 detection module is often used in critical applications such as power generation, oil and gas production, and chemical processing, where the reliable operation of rotating machinery is essential for the safe and efficient operation of the facility. By providing real-time monitoring and analysis of machinery vibration, the module helps to detect and diagnose potential problems before they result in equipment failure or downtime.

Overall, the Bently 60M100-00 detection module is a high-performance component that provides accurate and reliable monitoring of machinery vibration in critical applications, helping to ensure safe and efficient operation of rotating machinery.