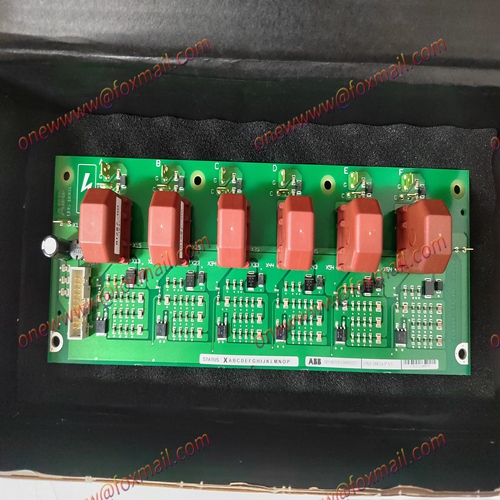

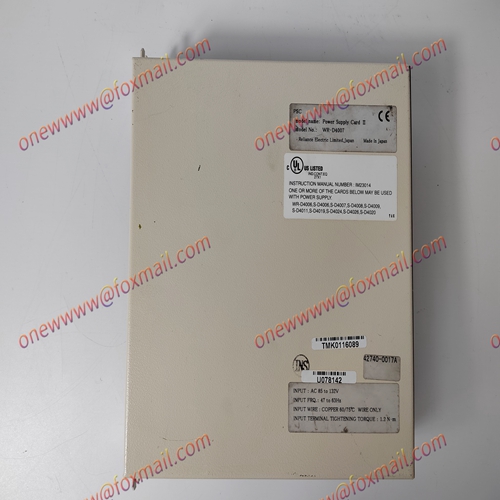

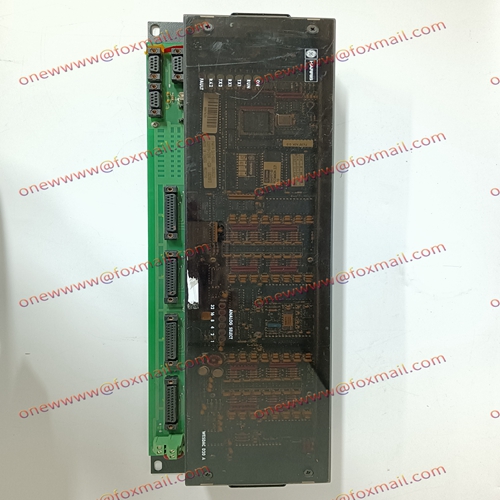

ABB REF601 CE446BB1NH feeder protection control relay details

The ABB REF601 CE446BB1NH is a digital feeder protection relay designed to protect electrical power systems against faults and abnormal operating conditions. Here are some details about this relay:

- Feeder protection: Provides protection against overcurrent, under/overvoltage, negative sequence, thermal overload, and other types of electrical faults.

- Measuring and monitoring: Measures and monitors a wide range of electrical parameters, such as current, voltage, frequency, and power, to detect abnormal conditions and provide early warning of potential problems.

- Communication: Provides various communication interfaces, such as Ethernet, serial ports, and I/Os, to enable remote monitoring, control, and data exchange with other devices and systems.

- Configuration: Offers a user-friendly interface for configuration, programming, and data analysis using software tools such as PCM600 or REU615.

- Reliability: Designed to operate in harsh environments with high levels of electromagnetic interference and extreme temperatures, ensuring high reliability and availability of the electrical power system.

- Certifications: Complies with various international standards, such as IEC 61850, IEC 60870-5, and IEEE C37.118, and holds multiple certifications, such as CE and UL, ensuring high-quality and safety.

The ABB REF601 CE446BB1NH feeder protection control relay is a versatile and reliable device that can be used in various electrical power systems, such as distribution networks, renewable energy plants, and industrial facilities, to ensure safe and efficient operation. If you require more specific information about this relay, please refer to the product documentation or contact ABB directly for assistance.

.jpg)

.jpg)

.jpg)