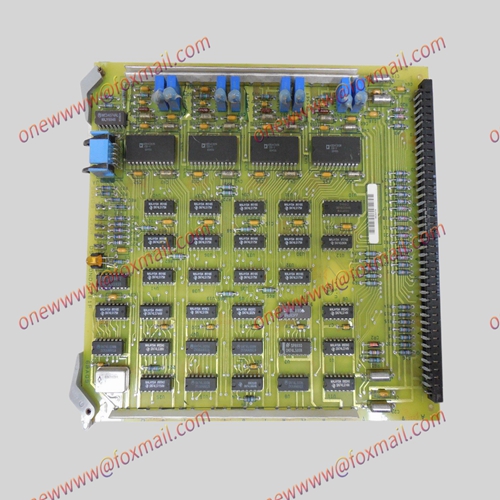

GE IS200EROCHIA PLC controller card parameter specifications

Here are the parameter specifications for the GE IS200EROCHIA PLC controller card:

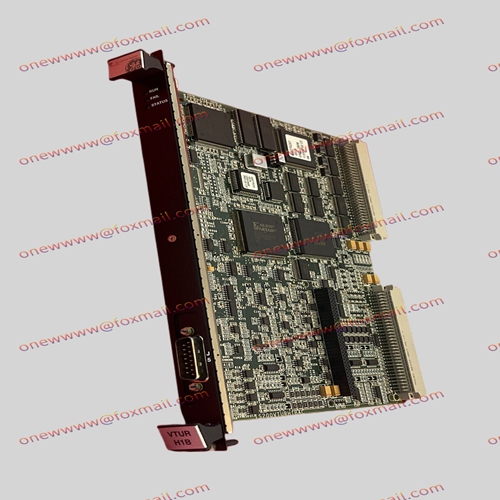

- Processor: The card features a high-speed microprocessor for fast and accurate control of industrial processes.

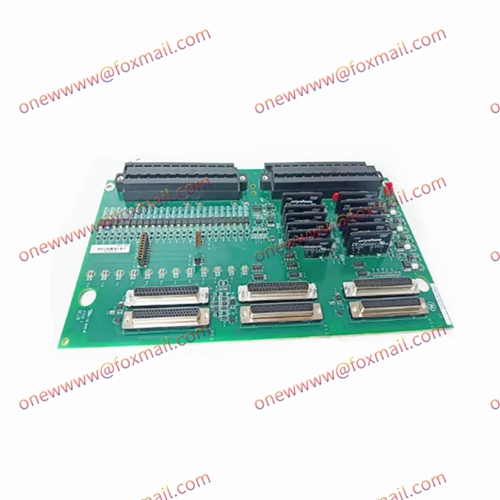

- Input/Output (I/O) architecture: The card has a flexible I/O architecture, with support for a wide range of I/O modules, including analog and digital inputs and outputs.

- Programming software: The card can be programmed using GE’s Proficy Machine Edition software, which provides a range of programming and diagnostic tools.

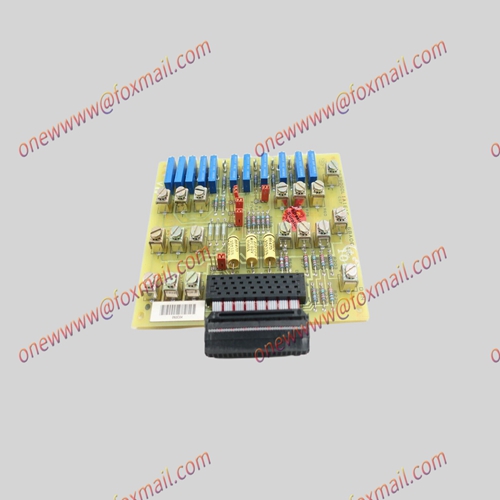

- Operating temperature: The card is designed to operate in a wide temperature range of -40°C to 70°C, making it suitable for use in harsh industrial environments.

- Ingress protection: The card is designed to provide protection against dust and water ingress, with an IP30 rating.

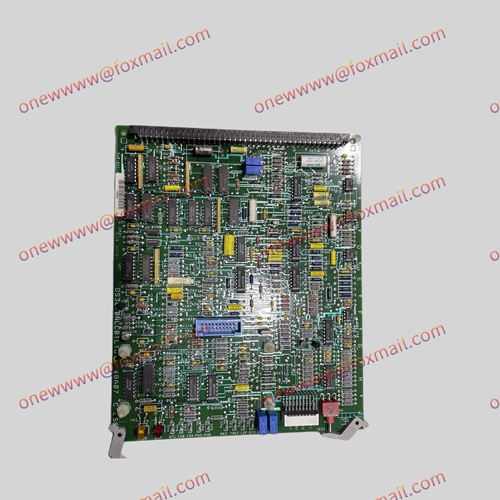

- Safety features: The card has integrated safety features, such as fail-safe modes and emergency shutdown capabilities, ensuring safe and reliable operation.

- Compatibility: The card is compatible with the RX3i and RX7i PACSystems families of controllers by GE.

- Communication protocols: The card supports a range of communication protocols, including Ethernet/IP, Modbus TCP, and Profibus DP.

- Memory: The card has 32 MB of user memory, which can be expanded with an optional flash memory module.

- Power consumption: The card has a power consumption of 3 watts.

Overall, the GE IS200EROCHIA PLC controller card is a powerful and flexible solution for industrial automation and control applications. Its advanced processing capabilities, flexible I/O architecture, and integrated safety features make it an ideal choice for a wide range of industrial applications.