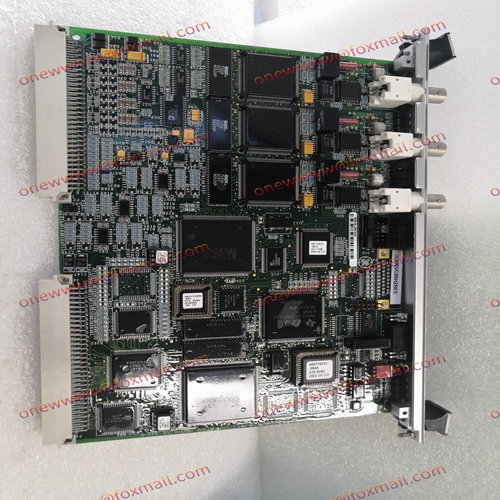

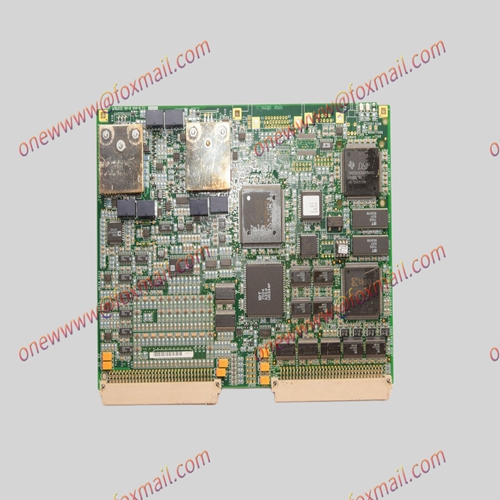

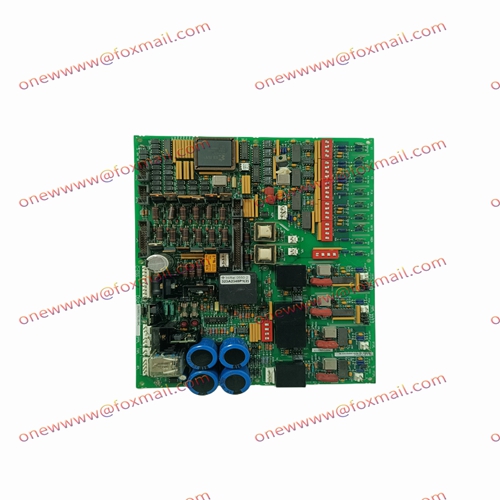

GE Programmable Gas Turbine Card DS200DSFBG2A

The GE Programmable Gas Turbine Card DS200DSFBG2A is a spare part used in gas turbine control systems manufactured by General Electric (GE). It is a highly flexible and versatile digital module that provides advanced control and monitoring capabilities for gas turbine systems.

Some of the key features of the GE Programmable Gas Turbine Card DS200DSFBG2A include:

- High-performance processing: The module is equipped with a powerful digital signal processor that enables high-speed processing and control of various gas turbine functions.

- Flexible configuration: The DS200DSFBG2A module offers a variety of I/O configurations, including digital input, digital output, analog input, and analog output. It also supports a range of communication protocols, including Modbus RTU, Profibus DP, and Ethernet/IP, allowing for seamless integration with different control systems.

- Robust construction: The module is designed to withstand harsh industrial environments, with a rugged metal housing and protection against electromagnetic interference and vibration.

- Advanced diagnostics: The DS200DSFBG2A module includes advanced diagnostics that allow for real-time monitoring of gas turbine status and troubleshooting of any issues that may arise.

- Easy installation and maintenance: The module features a user-friendly interface and plug-and-play connections, simplifying installation and maintenance procedures.

Overall, the GE Programmable Gas Turbine Card DS200DSFBG2A is a highly reliable and versatile solution for gas turbine control applications, offering high-performance processing, flexible configuration options, robust construction, advanced diagnostics, and easy installation and maintenance. It is a popular choice for gas turbine technicians and engineers in a variety of industries, including oil and gas, power generation, and manufacturing.