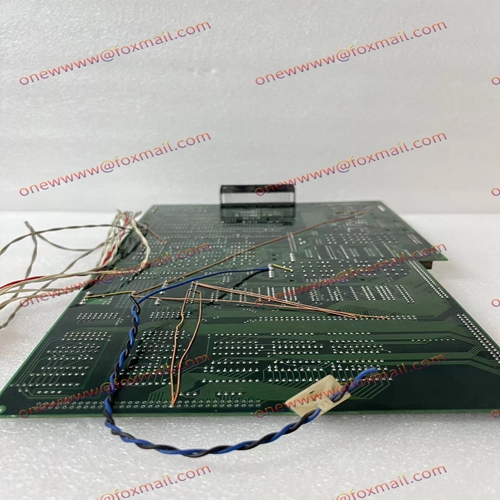

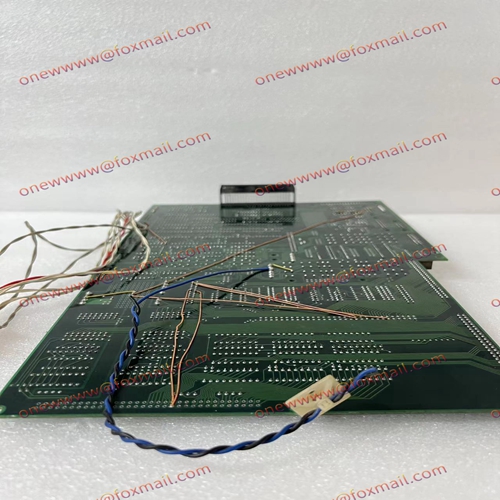

KOKUSAI BALEXT-SMP main control circuit board explain

The KOKUSAI BALEXT-SMP main control circuit board is an electronic circuit board used in the KOKUSAI BALEXT-SMP series of semiconductor manufacturing equipment. It is designed to provide control and monitoring capabilities for the various processes involved in semiconductor manufacturing.

The main control circuit board includes a powerful microcontroller and a variety of digital and analog inputs and outputs. It communicates with other components in the equipment using a variety of communication protocols such as RS-232, Ethernet, and GPIB.

The circuit board is responsible for controlling a variety of processes involved in semiconductor manufacturing, including temperature control, gas flow control, pressure control, and process timing. It also includes advanced monitoring capabilities such as fault detection and diagnostic functions, which allow operators to quickly identify and troubleshoot any issues that arise during the manufacturing process.

The KOKUSAI BALEXT-SMP main control circuit board is designed to be highly reliable, with redundant power supplies and communication ports to ensure continuous operation. It is also designed to be easily integrated into existing semiconductor manufacturing equipment, with support for a variety of software and communication protocols.

Overall, the KOKUSAI BALEXT-SMP main control circuit board is a critical component of the KOKUSAI BALEXT-SMP series of semiconductor manufacturing equipment. It provides advanced control and monitoring capabilities for the various processes involved in semiconductor manufacturing, and is designed to be highly reliable and easy to integrate into existing manufacturing equipment.