ABB PDP800 module

Technical data of product parameters

Typical temperature variation in the connecting volume of the 2.5 L/s LFS during a meter calibration is shown in Figure 8.

The LFS starts the calibration at the flow (2.0 L/s) such that the friction within the LFS warms the fluid by approximately PDP8000.2 K, following this warming as the flow decreases the temperature change diminishes. This and other test data show

that the maximum temperature change over time or difference between any two sensors among the sensor locations is

0.4 K or less during a data collection interval. The NIST LFSs have the capability of taking the temperature (and pressure

for the 2.5 L/s LFS) at the beginning and at the end of a data collection and corrections for gradient effects and mass

storage effects are made, making uncertainties due to temporal variations in temperature negligible. Since 5 temperature

sensors are distributed in the connecting volume, spatial temperature uncertainties are negligible too. However, if the

initial and final temperatures (and pressure) are not known, the temporal uniformity of the temperature sensors during a PDP800calibration can be used as a guide to assign an uncertainty to gradient and mass storage effects. That is, the temperature

change between data collection intervals can give insight to the values of the initial and final temperatures. For example,

if temperature control in a standard is poor and only the average temperature during a flow point is recorded, the rate of PDP800change of the temperature between data points can be used as a guide in determining what the initial and final

temperatures are. For illustration purposes, Figure 9 shows the temperature in a fictitious flow standard that is not well

controlled. Data points are taken every 30 seconds and the temperature is changing by 2 K between consecutive flow

points. Therefore, it can be assumed that the temperature change during the collection of a flow point is as high as

0.07 K/s. The time of the flow point collection multiplied by this rate of change will give an approximation of the change

in initial and final temperatures during the collection and hence an uncertainty can be assigned.

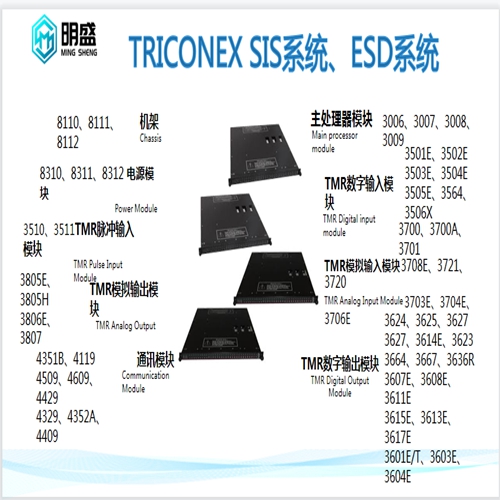

Product picture display

bout us service idea

We are able to supply equipment and spare parts from different countries and manufacturers. We can solve the trouble you find in many places or worry about the quality of our products. We have great advantage on the price, E-mail the detailed information of our products. We sincerely welcome you to inquire by phone or use!

With the business philosophy of “professionalism, integrity, innovation, cooperation and win-win”, we continue to develop new products, provide high-quality services to customers, pursue customer satisfaction to the maximum extent, and continue to develop new areas of business.

Email: onewwww@foxmail.com

Introduction to main products

Focus on DCS, PLC, robot control system and large servo system.

Main products: various modules/cards, controllers, touch screens, servo drives.

Advantages: supply imported original products, professional discontinued parts, fast delivery, accurate delivery time,

Main brands include ABB Bailey, GE/FANC, FOXBORO, Invensys TRICONEX, Bentley BENTLY, A-B Rockwell, Emerson EMERSON, OVATION, MOTOROLA, XYVOM, Honeywell HONEYWELL, Rexroth, KUKA, NI, DEIF, Yokogawa, Woodward WOODWARD, Ryan, Schneider SCHNEIDER, Yaskawa, Moog MOOG, PROSOFT and other brands

reminder

For more products, please contact the email for inquiry onewwww@foxmail.com

This article from the temporal Ming sheng automation equipment co., LTD.,

link: http:www.onewwww.com

Reviews

There are no reviews yet.