ABB REG216 Intelligent Industrial Robot

Technical data of product parameters

ABB REG216 intelligent industrial robot is a robot in the ABB robot series that can be used for various tasks of various scales. ABB robots are easy to install, program, operate, and expand, and can handle tasks of various scales. ABB is one of the world’s leading suppliers of robotics and mechanical automation, focusing on providing a complete product portfolio of robots, autonomous mobile robots, and mechanical automation solutions. Through ABB’s independent software design and integration, it creates higher value for customers.

The ABB REG216 robot is a multi joint robot with six rotation axes, each of which can be rotated to a specific angle to achieve the desired motion. This robot can be used for various applications in the field of industrial automation, such as material handling, welding, and assembly. The ABB REG216 robot has a maximum payload of 6 kilograms, a working radius of 910 millimeters, and a repeated positioning accuracy of ± 0.02 millimeters [5].

ABB REG216 robots can be programmed using ABB’s RobotStudio software. RobotStudio is ABB’s simulation and programming software that helps users simulate and test robot programs before actual robot operations. This software provides a virtual environment in which users can create robot models and program. Users can use RobotStudio software for offline programming and then upload the programming code to the robot controller. This can reduce the downtime of the production line and improve production efficiency [6].

In addition to RobotStudio, ABB robots also support other programming languages and development environments. For example, users can write robot programs using the RAPID programming language on ABB robot controllers. RAPID is a high-level programming language that can be used to write robot programs and other automated tasks. RAPID has structures similar to C++and Java, including variables, conditional statements, and loop statements. In addition, ABB robots also support other programming environments, such as Matlab and LabVIEW [7].

In summary, ABB REG216 intelligent industrial robot is a robot in the ABB robot series that can be used for various tasks of various scales. The robot has multiple joints, a maximum payload of 6 kilograms, and a working radius of 910 millimeters. Users can program the robot using RobotStudio software or other programming languages and development environments.

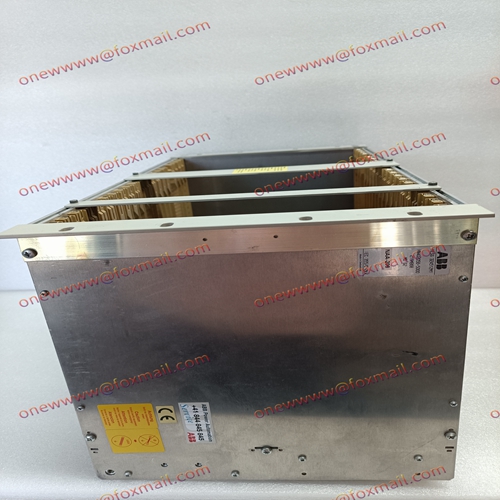

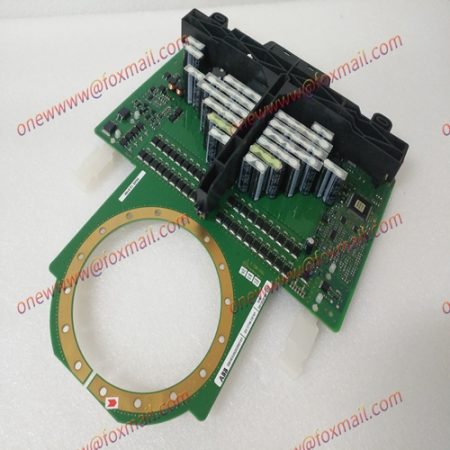

Product picture display

About us

Ruichang Mingsheng A company specializing in the sales of module spare parts for world-renowned brands (DCS systems) (robotic systems) (large-scale servo control systems), the company’s products include distributed control systems (DCS), programmable controllers (PLC), MOTOROLA MVME industrial modules, industrial control communication converters (Anybus), remote output/input modules (RTU), industrial computers (IPC), industrial low screen screens (IPC) HMI SCSI (50, 68, 80 Pin) AnyBus (Gateway) has become a global sales enterprise of industrial automation spare parts and components.

Email: onewwww@foxmail.com

Introduction to main products

Focus on DCS, PLC, robot control system and large servo system.

Main products: various modules/cards, controllers, touch screens, servo drives.

Advantages: supply imported original products, professional discontinued parts, fast delivery, accurate delivery time,

Main brands include ABB Bailey, GE/FANC, FOXBORO, Invensys TRICONEX, Bentley BENTLY, A-B Rockwell, Emerson EMERSON, OVATION, MOTOROLA, XYVOM, Honeywell HONEYWELL, Rexroth, KUKA, NI, DEIF, Yokogawa, Woodward WOODWARD, Ryan, Schneider SCHNEIDER, Yaskawa, Moog MOOG, PROSOFT and other brands

reminder

For more products, please contact the email for inquiry onewwww@foxmail.com

This article from the temporal Ming sheng automation equipment co., LTD.,

link: http:www.onewwww.com

Reviews

There are no reviews yet.