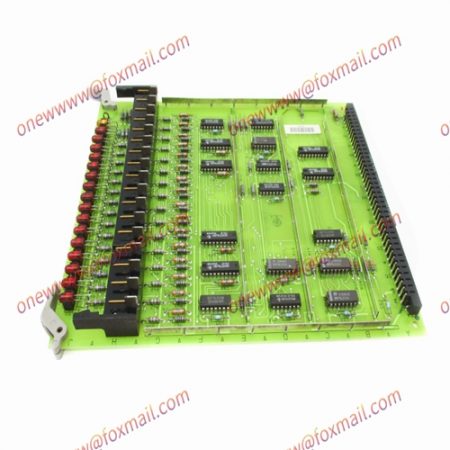

GE DS200UPLAG1ADC Industrial Control DCS System

Product Details Introduction

The GE DS200UPLAG1ADC is a specific model of an industrial control system used in Distributed Control System (DCS) applications. While I don’t have access to the specific details of this particular model, I can provide you with a general overview of industrial control DCS systems and their typical functionalities.

A Distributed Control System (DCS) is a type of control system used in various industries to monitor and control industrial processes. It consists of multiple control units distributed throughout a plant or facility, interconnected by a network, and working together to control different aspects of the process.

Here are some key features and functionalities that are typically found in industrial control DCS systems:

- Control and Monitoring: DCS systems provide control and monitoring capabilities for a wide range of industrial processes, including manufacturing, power generation, oil and gas, and more. They enable operators to monitor process variables, such as temperature, pressure, flow, and level, and control actuators to maintain optimal process conditions.

- Distributed Architecture: DCS systems have a distributed architecture, where multiple control units or controllers are deployed throughout the plant. This allows for efficient control and monitoring of various process areas and facilitates decentralized decision-making.

- Redundancy and High Availability: DCS systems often incorporate redundancy mechanisms to ensure high availability and reliability. Redundant controllers and communication networks are used to minimize the risk of system failures and provide continuous operation.

- Human-Machine Interface (HMI): DCS systems typically include a graphical interface known as the Human-Machine Interface (HMI). The HMI provides operators with a visual representation of the process, real-time data visualization, alarms, trends, and control options to interact with the system.

- Communication and Integration: DCS systems are designed to integrate with other devices and systems within the plant. They support various communication protocols to interface with field devices, such as sensors and actuators, as well as higher-level systems like supervisory control and data acquisition (SCADA) systems and enterprise resource planning (ERP) systems.

- Alarm Management: DCS systems provide comprehensive alarm management features to notify operators of abnormal or critical conditions in the process. This helps operators respond quickly and take appropriate actions to mitigate potential issues.

Product picture display

Related products:

Reviews

There are no reviews yet.