GE IS200TPROS1CBB IS230TSPRH1C MRP680538 spare parts module

Technical data of product parameters

Reconnect the gas source. Using the flow regulator, adjust the flow rate to 25% of

full scale flow. Check the flow rate indicated against the flow calibrator. Adjust the setting for potentiometer [R33] by using the insulated screwdriver through the access

window, until the output of the flow meter reads Using the flow regulator, increase the flow rate to 50% of full scale flow. Check the

flow rate indicated against the flow calibrator. The output of the flow meter should

read 2.50VDC ±63mV (or 12mA ±0.25mA). If the reading is outside of that range, IS200TPROS1CBB IS230TSPRH1C MRP680538

place the jumper at [J1] as appropriate to increase or decrease the signal. Adjust

the setting for potentiometer [R38] by using the insulated screwdriver through the

access window, until reading is within specification.Using the flow regulator, increase the flow rate to 75% of full scale flow. Check the

flow rate indicated against the flow calibrator. The output of the flow meter should

read 3.75VDC ±63mV (or 16mA ±0.25mA). If the reading is outside of that range,

place the jumper at [J2] as appropriate to increase or decrease the signal. Adjust IS200TPROS1CBB IS230TSPRH1C MRP680538

the setting for potentiometer [R39] by using the insulated screwdriver through the

access window, until reading is within specification.Using the flow regulator, increase the flow rate to 100% of full scale flow. Check

the flow rate indicated against the flow calibrator. The output of the flow meter

should read 5.00VDC ±63mV (or 20mA ±0.25mA). If the reading is outside of that

range, place the jumper at [J3] as appropriate to increase or decrease the signal.

Adjust the setting for potentiometer [R40] by using the insulated screwdriver

through the access window, until reading is within specification.To change the decimal place on the LCD display readout, simply move the jumper

to the appropriate location on the 8-pin header block. The numbers are printed to

the side of the connections. Do not attempt to place more than one jumper for IS200TPROS1CBB IS230TSPRH1C MRP680538

decimal setting.Your Mass Flow Meter was thoroughly checked at numerous quality control points

during and after manufacturing and assembly operations. It was calibrated

according to your desired flow and pressure conditions for a given gas or a mixture of gases.

It was carefully packed to prevent damage during shipment. Should you feel that

the instrument is not functioning properly please check for the following common

conditions firs

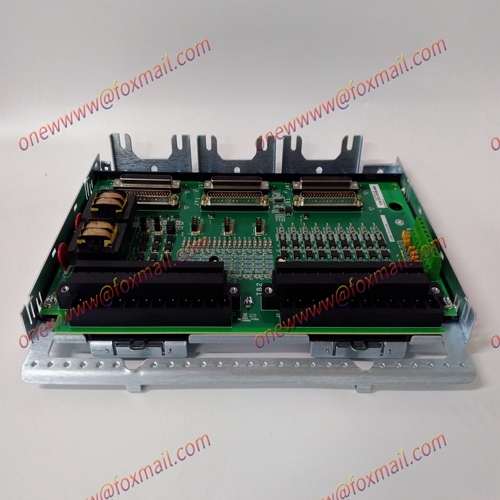

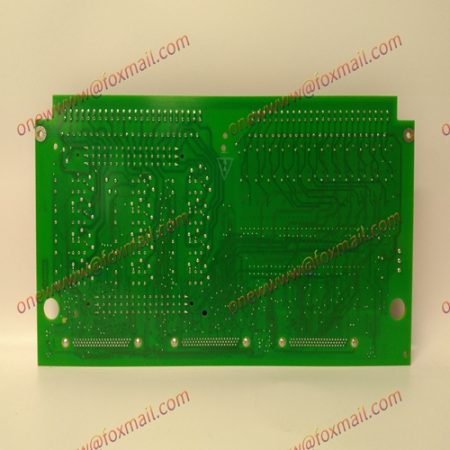

Product picture display

bout us service idea

We are able to supply equipment and spare parts from different countries and manufacturers. We can solve the trouble you find in many places or worry about the quality of our products. We have great advantage on the price, E-mail the detailed information of our products. We sincerely welcome you to inquire by phone or use!

With the business philosophy of “professionalism, integrity, innovation, cooperation and win-win”, we continue to develop new products, provide high-quality services to customers, pursue customer satisfaction to the maximum extent, and continue to develop new areas of business.

Email: onewwww@foxmail.com

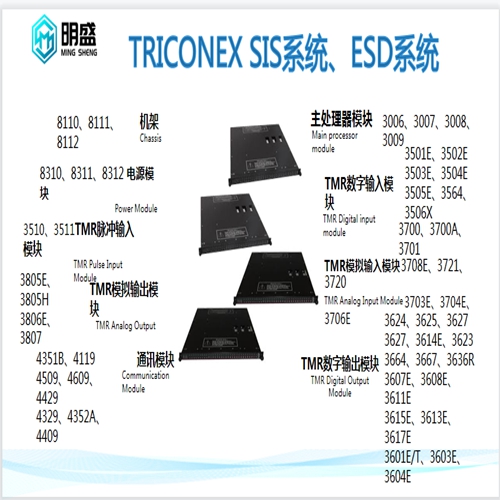

Introduction to main products

Focus on DCS, PLC, robot control system and large servo system.

Main products: various modules/cards, controllers, touch screens, servo drives.

Advantages: supply imported original products, professional discontinued parts, fast delivery, accurate delivery time,

Main brands include ABB Bailey, GE/FANC, FOXBORO, Invensys TRICONEX, Bentley BENTLY, A-B Rockwell, Emerson EMERSON, OVATION, MOTOROLA, XYVOM, Honeywell HONEYWELL, Rexroth, KUKA, NI, DEIF, Yokogawa, Woodward WOODWARD, Ryan, Schneider SCHNEIDER, Yaskawa, Moog MOOG, PROSOFT and other brands

reminder

For more products, please contact the email for inquiry onewwww@foxmail.com

This article from the temporal Ming sheng automation equipment co., LTD.,

link: http:www.onewwww.com

Reviews

There are no reviews yet.