MAESTRO 60X714 control module card

Technical data of product parameters

frequency and temperature instrumentation). NIST-owned and controlled instruments (temperature, etc.) are used as part

of the test of a customer’s meter since these have established uncertainty values based on calibration records maintained

as part of NIST’s Quality System: http://www.nist.gov/qualitysystem/index.cfm. Such information is not available for the MAESTRO 60X714

customer’s instrumentation. Use of the customer’s instrumentation for a calibration or Special Test requires specific

arrangements with the NIST technical contact. Calibration of customer’s ancillary instrumentation is not part of the

calibration procedures described here and would require that separate arrangements be made.

Following calibration, meters are rinsed with ethanol and dried. This precaution avoids contaminating customers’ fluids

with water that remains in the meter and it prevents corrosion of any part of the meter that is incompatible with water.

Most meters can be simply rinsed with alcohol using a hand held squirt bottle, or capped, filled with alcohol, inverted

several times to fill and mix trapped volumes, and drained. Some meters (e.g. positive displacement meters) may have

crevices that retain water if not rinsed more aggressively. NIST rinses such meters in a recirculating flow of ethanol at MAESTRO 60X714

approximately 15 % of the maximum flow for a minimum of five minutes. During the rinse, the meter is installed so that

the RF or magnetic pickoff of the positive displacement meter is positioned downward. This precaution assures that all

water is removed from the relatively small cavity enclosing the pickup if the meter has such a cavity. There are multiple

acceptable ways to dry flow meters: 1) application of vacuum, 2) application of a stream of dry gas , and 3) by hanging MAESTRO 60X714

and waiting for draining and evaporation. For turbine and positive displacement meters, one end of the meter is capped

while vacuum is applied to the other for one hour. This method avoids over-spinning the turbine or PD meter that might

occur if too strong a stream of dry gas is applied. However, Coriolis meters are dried using a stream of dry nitrogen

because it is quicker and over-spinning is not a concern with this meter type. In the event that no vacuum or inert gas is

available, meters are hung to dry at various orientations for a minimum of three hours at each orientation to be sure all

void volumes in the meter have drained dry.

Product picture display

bout us service idea

We are able to supply equipment and spare parts from different countries and manufacturers. We can solve the trouble you find in many places or worry about the quality of our products. We have great advantage on the price, E-mail the detailed information of our products. We sincerely welcome you to inquire by phone or use!

With the business philosophy of “professionalism, integrity, innovation, cooperation and win-win”, we continue to develop new products, provide high-quality services to customers, pursue customer satisfaction to the maximum extent, and continue to develop new areas of business.

Email: onewwww@foxmail.com

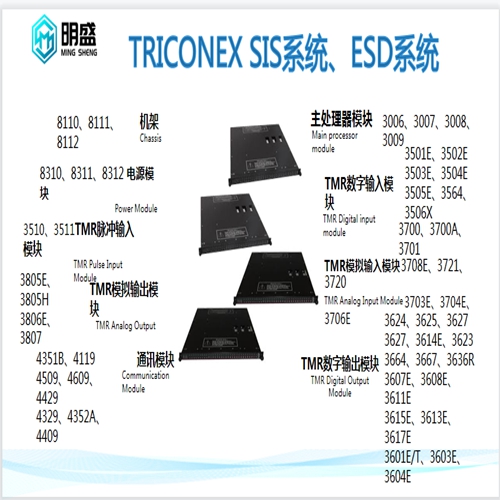

Introduction to main products

Focus on DCS, PLC, robot control system and large servo system.

Main products: various modules/cards, controllers, touch screens, servo drives.

Advantages: supply imported original products, professional discontinued parts, fast delivery, accurate delivery time,

Main brands include ABB Bailey, GE/FANC, FOXBORO, Invensys TRICONEX, Bentley BENTLY, A-B Rockwell, Emerson EMERSON, OVATION, MOTOROLA, XYVOM, Honeywell HONEYWELL, Rexroth, KUKA, NI, DEIF, Yokogawa, Woodward WOODWARD, Ryan, Schneider SCHNEIDER, Yaskawa, Moog MOOG, PROSOFT and other brands

reminder

For more products, please contact the email for inquiry onewwww@foxmail.com

This article from the temporal Ming sheng automation equipment co., LTD.,

link: http:www.onewwww.com

Reviews

There are no reviews yet.