MVME55006E-0163 communication module warehouse stock

Technical data of product parameters

The web site gives instructions for ordering a calibration for domestic and foreign customers and has the sub-headings:

A.) Customer Inquiries, B.) Pre-arrangements and Scheduling, C.) Purchase Orders, D.) Shipping, Insurance, and Risk of

Loss, and E.) Turnaround Time. The web site also gives special instructions for foreign customers. The web address:

http://www.nist.gov/calibrations/mechanical_index.cfm has information more specific to the flow calibration service, MVME55006E-0163

including the technical contacts in the Fluid Metrology Group, fee estimates, and turnaround times.

Piston prover systems have long been accepted as primary flow standards for both gas and liquid flow meters [7,8].

Figure 1 shows NIST’s piston provers and Table 1 and Table 2 give their characteristics. Conceptually, a piston prover

consists of a circular cylinder of known internal diameter surrounding a sealed piston. This piston strokes through

measured lengths, at a constant speed, to prod uce a constant volumetric flow. The volumetric flow is calculated by MVME55006E-0163

dividing the swept volume by the time needed for the piston to traverse the measured length. Alternatively, a water draw

ref can be performed to determine the volumetric prover factor, ?V , which is the number of encoder pulses divided by the

volume of fluid pushed through the cylinder. Temperature (and pressure for the 2.5 L/s LFS) measurements at key

locations are used to assess the changes in fluid density and connecting volume that occur between the start and stop

times, allowing corrections for storage effects. The calibration fluid coefficient of thermal expansion is known, hence the

volumetric flow in the cylinder can be converted to the volumetric flow at the test section where the MUT is located (or

the mass flow can be calculated using the fluid density). The output of the MUT is acquired along with the necessary MVME55006E-0163

piston measurements so that a verage flows from the MUT and the flow standard can be compared.

Two types of piston arrangements are used in these systems. An active piston can both drive and measure a volumetric

flow out of the cylinder (like a syringe), while a passive piston is pushed through the cylinder by pressure from a separate

pump. The 0.1 L/s LFS employs a passive piston and the 2.5 L/s LFS employs an active piston.

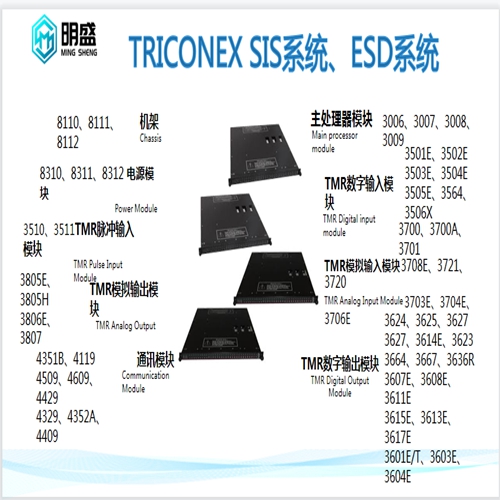

Product picture display

bout us service idea

We are able to supply equipment and spare parts from different countries and manufacturers. We can solve the trouble you find in many places or worry about the quality of our products. We have great advantage on the price, E-mail the detailed information of our products. We sincerely welcome you to inquire by phone or use!

With the business philosophy of “professionalism, integrity, innovation, cooperation and win-win”, we continue to develop new products, provide high-quality services to customers, pursue customer satisfaction to the maximum extent, and continue to develop new areas of business.

Email: onewwww@foxmail.com

Introduction to main products

Focus on DCS, PLC, robot control system and large servo system.

Main products: various modules/cards, controllers, touch screens, servo drives.

Advantages: supply imported original products, professional discontinued parts, fast delivery, accurate delivery time,

Main brands include ABB Bailey, GE/FANC, FOXBORO, Invensys TRICONEX, Bentley BENTLY, A-B Rockwell, Emerson EMERSON, OVATION, MOTOROLA, XYVOM, Honeywell HONEYWELL, Rexroth, KUKA, NI, DEIF, Yokogawa, Woodward WOODWARD, Ryan, Schneider SCHNEIDER, Yaskawa, Moog MOOG, PROSOFT and other brands

reminder

For more products, please contact the email for inquiry onewwww@foxmail.com

This article from the temporal Ming sheng automation equipment co., LTD.,

link: http:www.onewwww.com

Reviews

There are no reviews yet.