PLC controller card 8106-TI-RT module GE

Technical data of product parameters

If an interrupt 8106-TI-RT occurs while the SLC 5/03 (or higher) processor is performing

a multi-word slot update and your interrupt subroutine accesses that same slot,

the multi-word transfer completes prior to performing the interrupt

subroutine slot access.

Note that DII execution time adds directly to the overall scan time. During the

latency period, the processor is performing operations that cannot be

disturbed by the DII interrupt function. The Interrupt Latency Control Bit

(S:33/8) functions as follows. 8106-TI-RT

• When the bit is set (1) interrupts are serviced within the minimum time

possible. The time will vary depending upon which processor and

communication protocol you are using.

• The default state is cleared (0). When S:33/8 is clear (0), user interrupts

occur between rungs and I/O slot updates. To determine the interrupt

latency with S:33/8 clear, you must calculate the execution time of each

and every rung of your program, then the add the execution time of the

longest rung to the latency time.You can reconfigure the DII entirely or in part, depending on the particular

parameter(s) you choose. You can reconfigure some of the parameters simply 8106-TI-RT

by writing the new value over the old value. Other values require you to set the 8106-TI-RT

recon figuration bit in addition to writing the new value. The DII is

non-retentive and always reconfigures itself upon entry into the REM Run

mode. Refer to “DII Parameters” for details on reconfiguring each parameter.• DII Pending Bit (S:2/11) – When set, this bit indicates that the DII

Accumulator (S:52) equals the DII preset (S:50) and the ladder file

number specified by the DII File Number (S:46) is waiting to be

executed. It is cleared when the DII File Number (S:46) begins

executing, or on exit from the REM Run or REM Test mode.

• DII Enable Bit (S:2/12) – To program this feature, use the data monitor

function to set/clear this bit, or address this bit with your ladder

program. This bit is set in its default condition. If set, it allows execution

of the DII subroutine if the DII File Number (S:46) is non-zero. If clear,

when the interrupt occurs, the DII subroutine will not execute and the

DII Pending bit is be set. The DII function continues to run anytime

the DII file (S:46) is non-zero. If the pending bit is set, the enable bit is

examined at the next end of scan.

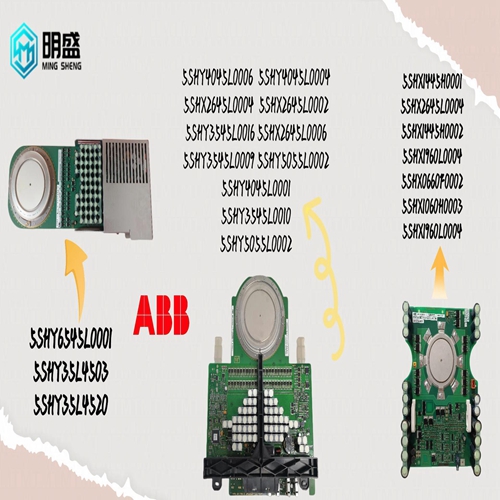

Product picture display

bout us service idea

The company takes production suspension control system parts and components as its dominant products

As long as it is what you want, I can help you find it! Good price! Our purpose:

Build customer relationship with sincerity

Obtain customer satisfaction through service

Win the trust of customers with products

Improve work efficiency with actions

Please contact us for the products you need urgently!

You can’t find the product. Please contact us!

Products you can’t buy. Please contact us!

Email: onewwww@foxmail.com

Introduction to main products

Focus on DCS, PLC, robot control system and large servo system.

Main products: various modules/cards, controllers, touch screens, servo drives.

Advantages: supply imported original products, professional discontinued parts, fast delivery, accurate delivery time,

Main brands include ABB Bailey, GE/FANC, FOXBORO, Invensys TRICONEX, Bentley BENTLY, A-B Rockwell, Emerson EMERSON, OVATION, MOTOROLA, XYVOM, Honeywell HONEYWELL, Rexroth, KUKA, NI, DEIF, Yokogawa, Woodward WOODWARD, Ryan, Schneider SCHNEIDER, Yaskawa, Moog MOOG, PROSOFT and other brands

reminder

For more products, please contact the email for inquiry onewwww@foxmail.com

This article from the temporal Ming sheng automation equipment co., LTD.,

link: http:www.onewwww.com

Reviews

There are no reviews yet.